Lean Requirements Management

Lean Requirements Management

Lean Requirements Management

Challenge: How do I establish efficient and effective Requirements Management (RM) within my large systems engineering project?

- How can I establish RM without driving overhead and building an expensive “time and effort sink”?

- Can RM enhancements provide me benefits beyond simple traceability?

Example: NASA NENS (Near Earth Networks Services)

Our Lean Requirements Management process emphasizes speed, accuracy, and efficiency through innovative automation

- Reduce the lead time involved in converting a System Requirements Document (SRD) into a library of logically linked (Level 3) system requirements, by automatically parsing SRD documents using advanced text searching algorithms.

- Create linked child requirements (Level 4 & 5) through automated scripting to quickly generate a Requirements Traceability Verification Matrix (RTVM)

- Enhance Integration and Test processes by leveraging automation to cascade I&T updates into the RTVM

Challenge: Conduct RM for Space Network communication platform upgrades within compressed schedules, using minimal resources.

Solution: Our staff engineered a Lean process, which automated tasks on the critical path to establish and maintain new projects. This process reduced resource needs by more than 50% when compared to traditional processes.

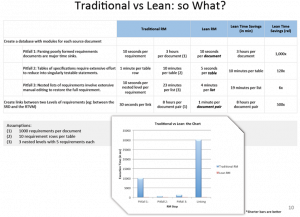

The graphic below depicts 3 common RM pitfalls, comparing Traditional RM against our Lean RM approach